- Tel: +86 15759270795

- Email: Sales@touchkey-china.com

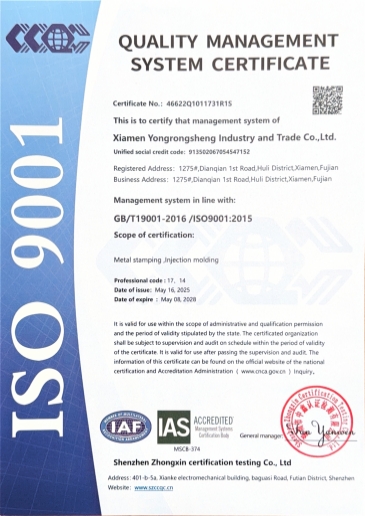

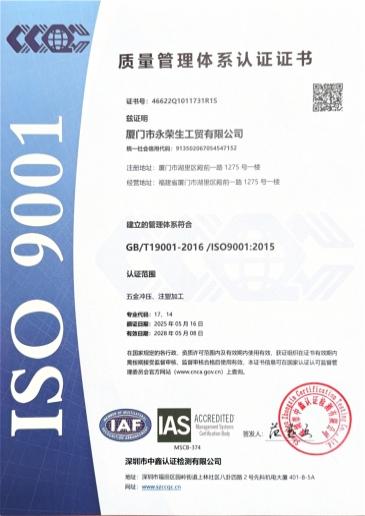

As an ISO9001-certified enterprise, we go beyond standard system processes. Goodkey focuses on three critical technical pillars to ensure every component meets the rigorous demands of global industrial leaders.

Consistency in precision manufacturing starts with experienced people. Our production team is exceptionally stable; as of 2026, our minimum working tenure is 7 years, while our senior technical staff exceeds 22 years of service. This deep institutional knowledge ensures that every complex touch spring is manufactured with expert precision.

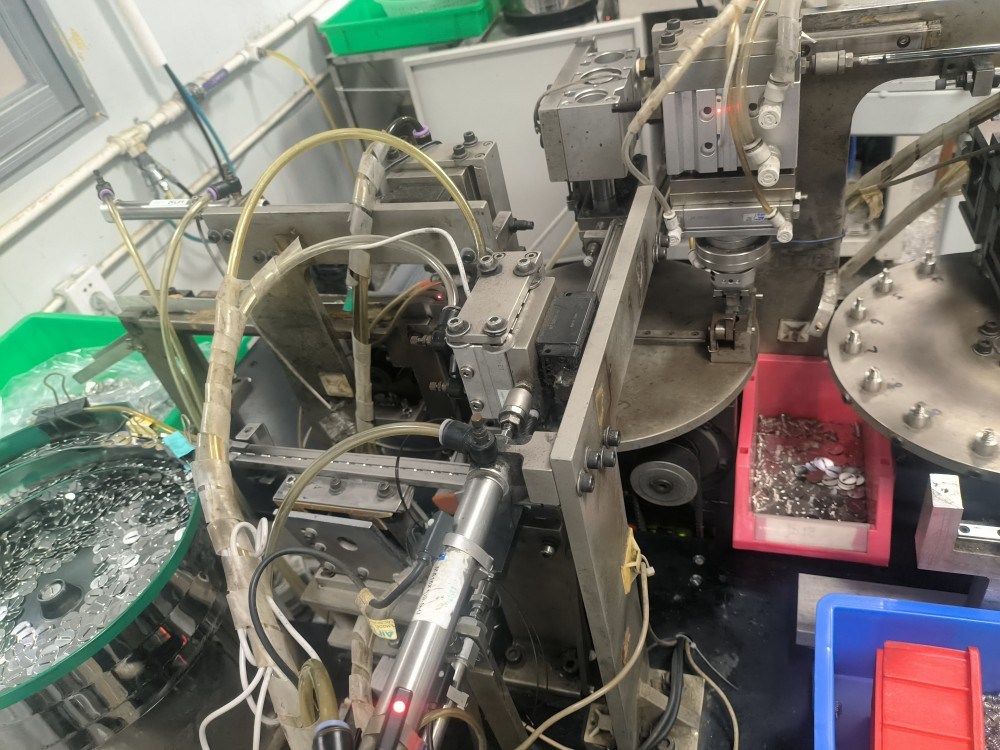

We believe automation is the only path to absolute quality consistency. We continuously invest in proprietary automated machinery to eliminate human error and enhance production efficiency.

Case in Point:

Our automated riveting line handles over 200,000 pieces daily with flawless precision.

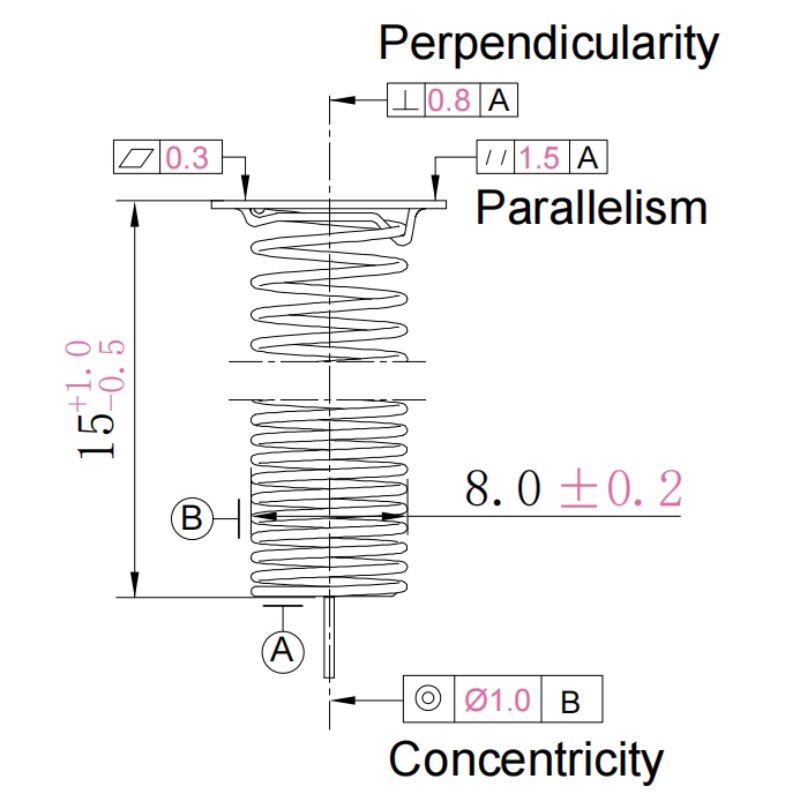

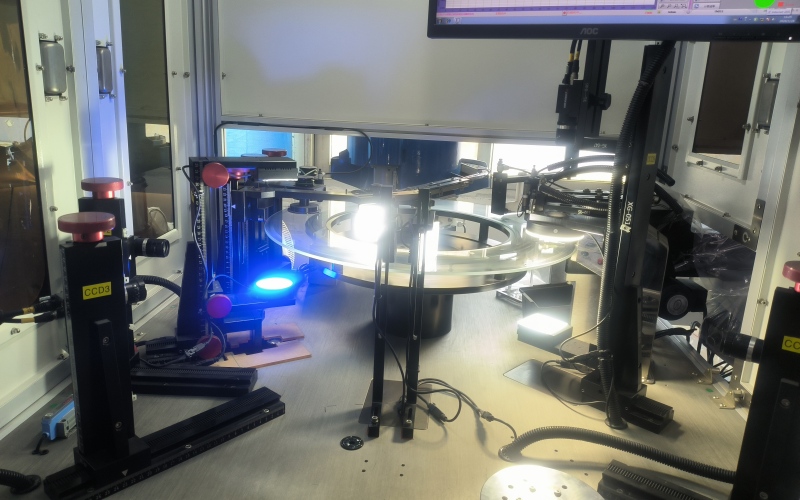

To guarantee zero-defect manufacturing, we have deployed two sets of self-developed online dimensional monitoring systems. Every single capacitive touch spring undergoes 100% visual inspection.

Our AOI systems monitor critical positional tolerances that standard testing might miss, including parallelism, perpendicularity, and concentricity.

Technical Capabilities:

Self-developed AOI machines ensuring 100% dimensional accuracy for industrial applications.

Precision is maintained through our self-developed Automated Optical Inspection (AOI) technology, ensuring zero-defect delivery for complex components:

Optical inspection machine for metal-plate capacitive touch spring |

Optical inspection machine for SMT metal stamping part |

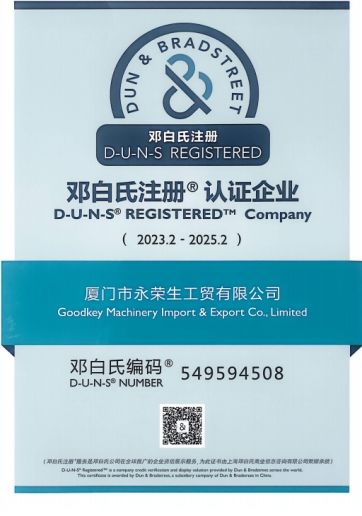

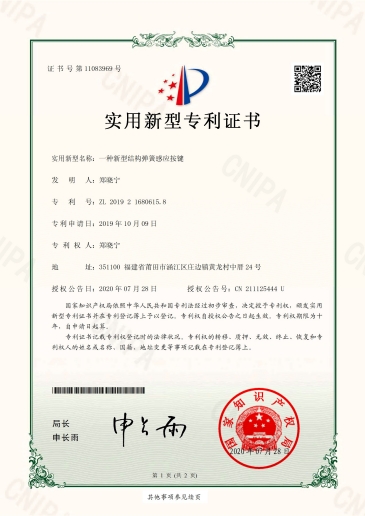

Goodkey is recognized for excellence in quality management and technical innovation within the capacitive touch industry.

ISO 9001: English Version |

ISO 9001: Chinese Version |

DUNS Registered |

Top 10 First-class Supplier |

Patent No: ZL 2019 2 1680615.8 |

Utility Model Patent Certificate |

Leave A Message

Scan to Wechat/Whatsapp :