- Tel: +86 15759270795

- Email: Sales@touchkey-china.com

Square Surface Capacitive Touch Spring are widely used in everyday life. Goodkey Machinery support OEM & ODM service of a variety type of touch springs in different fields.

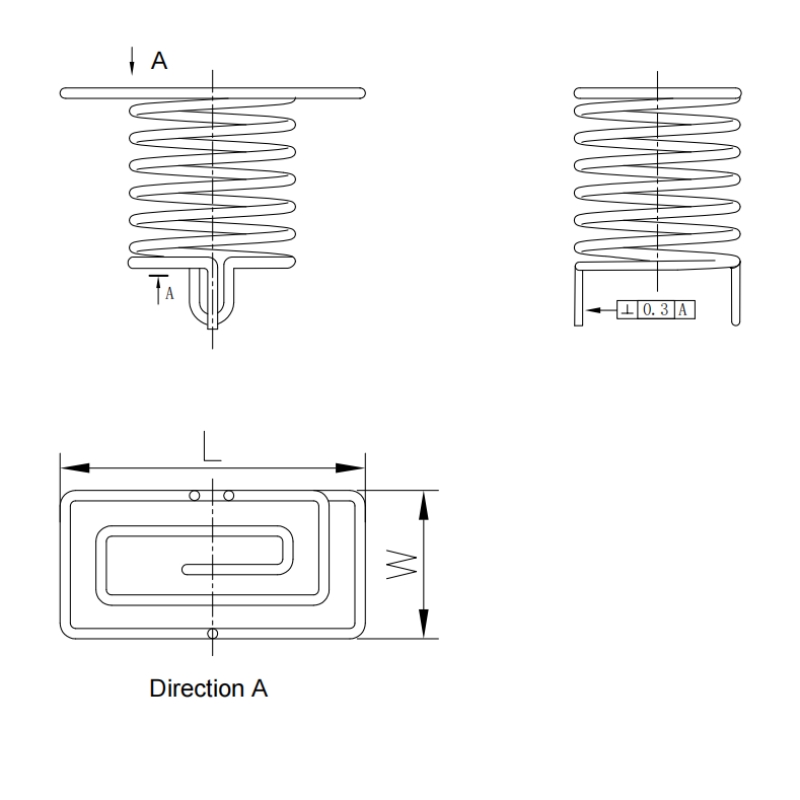

Main features of square surface capacitive touch spring:

Item No. :

RS-001Samples :

30~80pcs AvailableSurface Finish :

Nickel-plated, Tin-plated (Anti-corrosion)Material Options :

Stainless Steel, Carbon Steel, Music Wire, Phosphor BronzeOEM/ODM :

yesSquare Surface Capacitive Touch Spring

Product Specifications:

| Top Touch Diameter | According to your need (Square Surface) |

| Working Height | 5mm - 50mm (Customizable) |

| Welding Foot | One U-shaped, One U-shaped with a single pin, Two U-shaped (Or custom configuration) |

| Material Options | Stainless Steel, Carbon Steel, Music Wire, Phosphor Bronze |

| Surface Finish | Nickel-plated, Tin-plated (Anti-corrosion) |

* We provide professional OEM/ODM services of of touch springs. Contact us for custom drawings and samples via Sales@touchkey-china.com

How to quickly get some free samples for test

To ensure the highest precision, we recommend providing your technical drawings. We accept all major formats including PDF, DXF, DWG, STEP, and IGS.

Don't have a drawing yet? No problem. Simply provide the specifications listed below. Our engineering team will create a custom design for your Square Surface Capacitive Touch Spring and submit the drawings to you for final approval.

Standard Process: Upon approval of the technical drawing, we provide complimentary (free) samples. The standard production time for samples is approximately 3 weeks.

Urgent Service: For time-sensitive projects, we offer an expedited service. The entire process—from design to sample dispatch—can be completed within 1 week.

We have existing molds for the following sizes, which can save you tooling costs and time:

* Selecting from our ready-made specifications ensures zero tooling costs and the fastest delivery time. Custom sizes are available but will incur additional setup fees and extended lead times.

1. Bulk (Plastic bag)

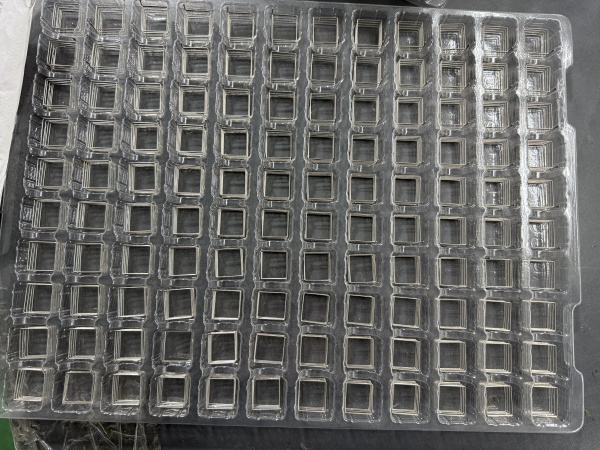

2. Plastic tray

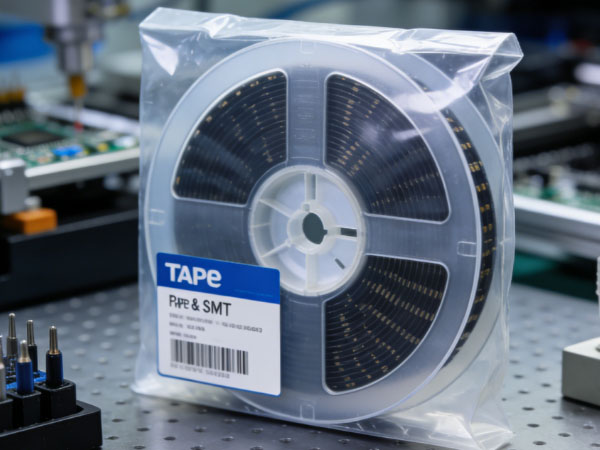

3. Tape & Reel (For SMT)

The capacitive touch springs can be applied in various fields such as household appliances, medical equipment, robotics, wearable technology, automated devices, tools, gas, instrumentation, automotive industries, and more. For example, the capacitive touch springs are now very commonly found in household appliances such as induction cookers, microwaves, ovens, refrigerators, air conditioners, coffee machines, and audio systems, and so on.

Leave A Message

Scan to Wechat/Whatsapp :