- Tel: +86 15759270795

- Email: Sales@touchkey-china.com

In addition to various types of capacitive touch buttons, Goodkey company, extension spring manufacturing since 2000, supply any common extension springs of different specifications.

Main features of common extension spring:

Item No. :

OCE-001Samples :

30~80pcs AvailableSurface Finish :

Nickel-plated, Tin-plated, Zinc-platedMaterial Options :

Phosphor Bronze, Beryllium Copper, Brass, Stainless steel, High-carbon steelOEM/ODM :

yesCustom Common Extension Spring

Product Specifications:

| Wire Diameter |

The diameter of the metal steel wire (Customizable) |

| Free Length | The overall length of the spring in its unloaded state, with all coils touching (Customizable) |

| Hook/Loop Types |

Full Loop, Half Hook, Extended Hook, or Double Twisted Full Loop |

| Material Options |

Phosphor Bronze, Beryllium Copper, Brass, Stainless steel, High-carbon steel, Alloy steel |

| Surface Finish | Nickel-plated, Tin-plated, Zinc-plated (Anti-corrosion) |

* We provide professional OEM/ODM services of common extension springs. Contact us for custom drawings and samples via Sales@touchkey-china.com

How to quickly get some free samples for test

To ensure the highest precision, we recommend providing your technical drawings. We accept all major formats including PDF, DXF, DWG, STEP, and IGS.

Don't have a drawing yet? No problem. Simply provide the specifications listed below. Our engineering team will create a custom design for your capacitive touch button and submit the drawings to you for final approval.

Standard Process: Upon approval of the technical drawing, we provide complimentary (free) samples. The standard production time for samples is approximately 3 weeks.

Urgent Service: For time-sensitive projects, we offer an expedited service. The entire process—from design to sample dispatch—can be completed within 1 week.

1. Bulk (Plastic bag)

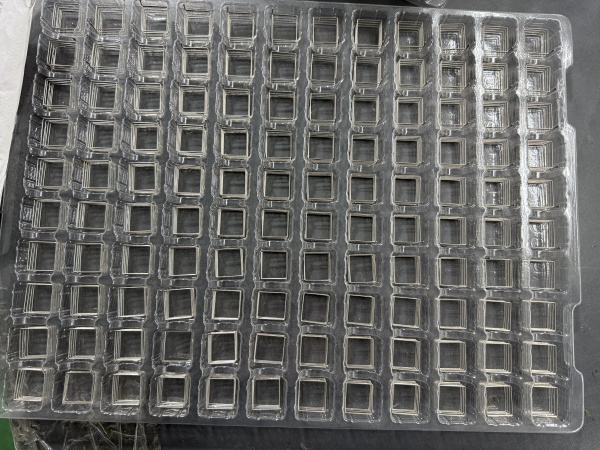

2. Plastic tray

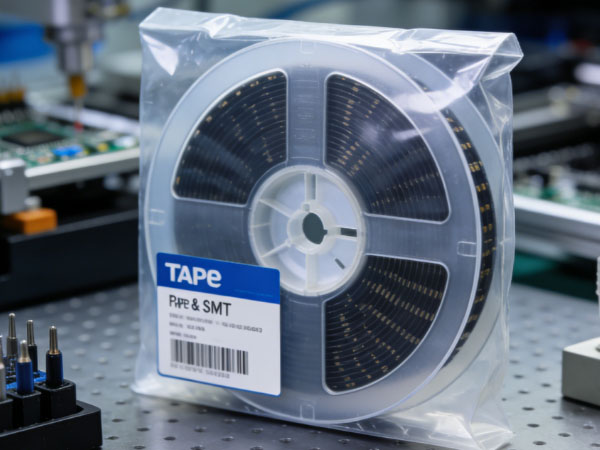

3. Tape & Reel (For SMT)

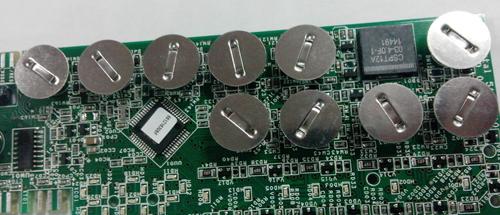

Common extension springs are essential for any assembly requiring a reliable return pull action. They are commonly applied in Automotive and Machinery (carburetors, farm machinery), Home Systems (screen door returns, garage door assemblies, washing machine balance systems), and Recreation (trampolines, toys). Additionally, they serve specialized roles in electronic assemblies and capacitive touch button configurations.

Leave A Message

Scan to Wechat/Whatsapp :