- Tel: +86 15759270795

- Email: Sales@touchkey-china.com

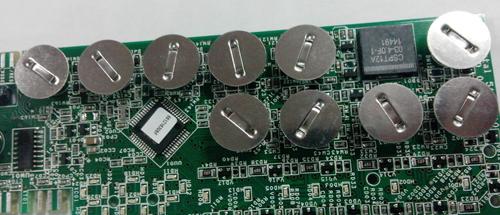

Surface mount metal stamping parts are widely used in everyday life. Goodkey can provide a one-stop service including component structure evaluation, mold development, production, tape & reel ribbon package etc.

Main features of surface mount metal stamping parts:

Item No. :

SS-001Samples :

30~80pcs AvailableSurface Finish :

Nickel-plated, Tin-plated (Anti-corrosion)Material Options :

Phosphor bronze(CuSn6), Brass High-carbon steel, Stainless steelOEM/ODM :

yesSurface Mount Metal Stamping Parts

Product Specifications:

| Tolerance Control | Real-time detection within ±0.05 mm |

| Inspection System | Visual inspection for diameter deviation >0.1mm |

| Material Options |

Phosphor bronze(CuSn6), Brass High-carbon steel, Stainless steel |

| Surface Finish | Nickel-plated, Tin-plated (Anti-corrosion) |

* We provide professional OEM/ODM services of stamping parts. Contact us for custom drawings and samples via Sales@touchkey-china.com

How to quickly get some free samples for test

To ensure the highest precision, we recommend providing your technical drawings. We accept all major formats including PDF, DXF, DWG, STEP, and IGS.

Don't have a drawing yet? No problem. Simply provide the specifications listed below. Our engineering team will create a custom design for your capacitive touch button and submit the drawings to you for final approval.

Standard Process: Upon approval of the technical drawing, we provide complimentary (free) samples. The standard production time for samples is approximately 3 weeks.

Urgent Service: For time-sensitive projects, we offer an expedited service. The entire process—from design to sample dispatch—can be completed within 1 week.

1. Bulk (Plastic bag)

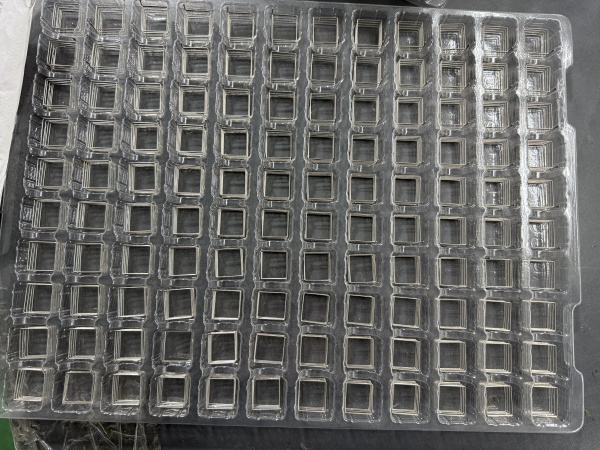

2. Plastic tray

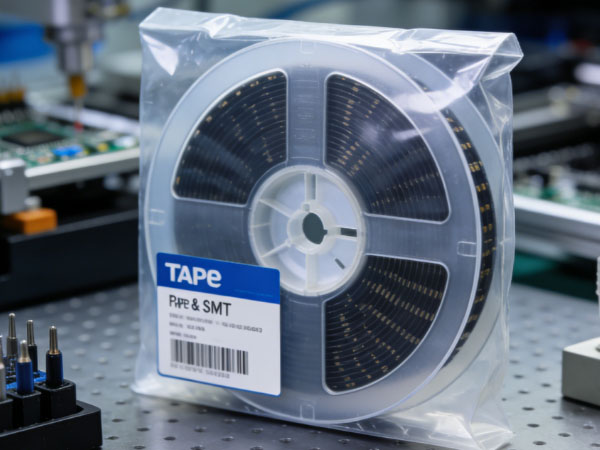

3. Tape & Reel (For SMT)

Goodkey has developed an advanced optical online dimensional inspection system specifically for high-volume SMT metal stamping production. This system monitors each component in real time, detecting dimensional tolerances within ±0.05 mm and identifying defective products with a diameter deviation of more than 0.1 millimeters. Any unqualified parts exceeding these tolerances are automatically rejected, ensuring the overall defective rate remains below 10 ppm for maximum assembly reliability.

Leave A Message

Scan to Wechat/Whatsapp :